Wait! Don't Overpay for Your Build.

Submit your project details now and receive a Free, Comprehensive Quote within 24 Hours.

Being Your Eyes on the Factory Floor: Why We Inspect Before We Ship

Trust is a currency. And when you are sending thousands of dollars to a supplier 5,000 miles away, that currency is expensive. We’ve all seen the online shopping failures where the product that arrives looks nothing like the photo. How do you prevent that when building a house? You can’t just fly to China every weekend to check on production. This is where PrimeBuildHub separates itself from a standard marketplace. They aren’t just a catalog; they are your Quality Control (QC) department.

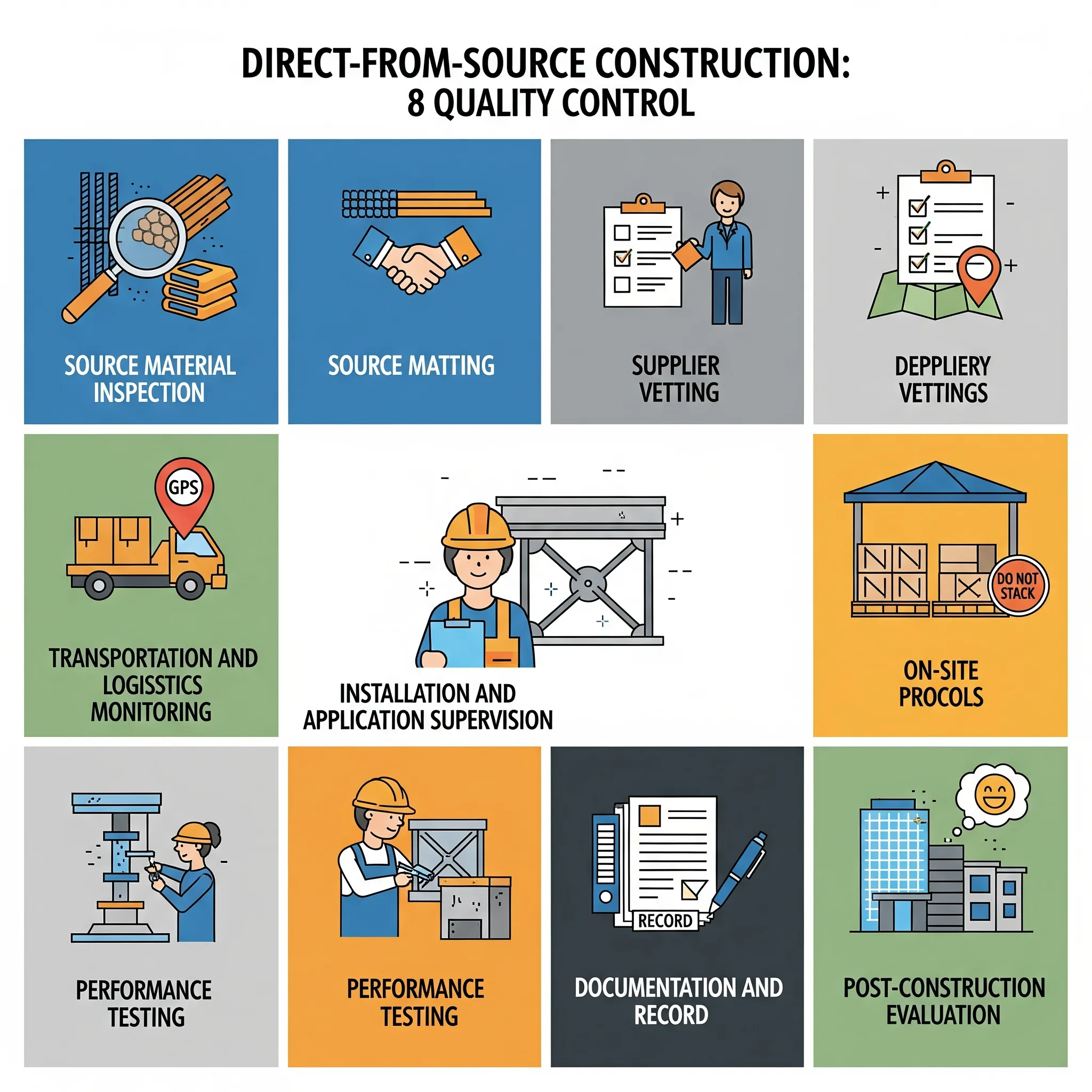

Quality starts before the product is even made. PrimeBuildHub’s “First Layer of Defense” is checking the raw materials. Is the moisture content of the wood low enough to prevent warping? Is the aluminum profile the correct thickness? If the ingredients are wrong, the final product will be bad. By catching these issues early, they prevent structural failures that could happen months down the line.

The most critical step is the Pre-Shipment Inspection (PSI). Once production is finished and the goods are sitting in the factory warehouse, a PrimeBuildHub inspector goes to the factory. They open a percentage of the boxes to verify three things: Dimensions (is the cabinetry exactly 600mm wide?), Color (does the tile batch match the sample you approved?), and Function (do the soft-close drawers actually soft-close?). If the product fails here, it stays in China to be fixed or remade. You never have to deal with the headache of receiving a defective product.

Even if the product is perfect, it still has to survive the ocean. The final check is Loading Supervision. The team physically watches the container being stuffed. They ensure heavy items like tiles are placed on the bottom, while fragile items like lights are secured on top. They check that pallets are strapped down and airbags are used to fill gaps so nothing shifts during a storm at sea. Broken glass is useless glass, and this step ensures your order arrives intact.

The result of this process isn’t just a container; it’s a QC Report. You receive a detailed document with photos and videos of your specific goods before the ship sails. You aren’t crossing your fingers and hoping for the best; you are verifying the reality. That layer of accountability is the difference between gambling on a purchase and professional procurement.